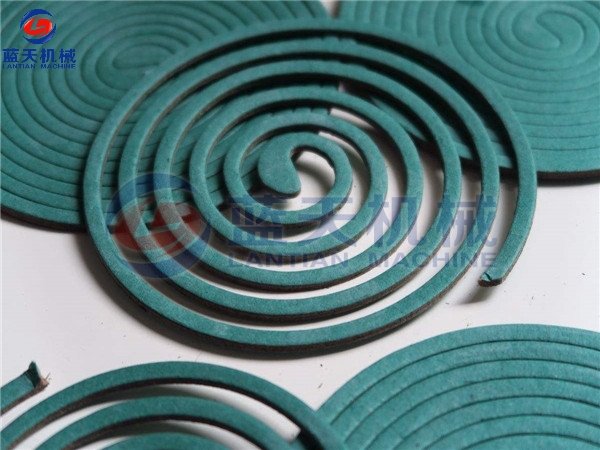

Mosquito coil is a daily mosquito repellent tool, after production, mosquito coil also contains a lot of water. At this time, we need to use our mosquito coil dryer to dry it in order to preserve its efficacy and color.

The mosquito coil drying process can also be divided into the following 3 stages.

① The starting temperature is controlled at 45℃, the humidity is controlled at 60%, and the baking time is 5-6 hours.

② Mid-term temperature adjustment to 50℃, baking for 3 hours.

③ The humidity is not adjusted during the drying period, and the temperature is adjusted to 55 ℃.

Our air-energy heat pump box mosquito coil dryer mainly bakes mosquito coil at medium and low temperatures, the dried mosquito coil not only preserves the original efficacy and color, but also does not warp and deform, and has high strength and is not fragile.

Kenyan customers have purchased Lantian brand paper tube dryer machine, our dryer is controlled by PLC intelligent control board, the temperature is adjustable,...

Lantian Brand industrial products dryer machine shipping to Canada

Kenya Customers

Return Top

Return Top